ssr engineering offers a very versatile laboratory exposure station for the most appropriate process evaluation. The exposure can be defined on basis of the parameters exposure time, radiation intensity and required UV dosage and is precisely controlled by an internal PLC.

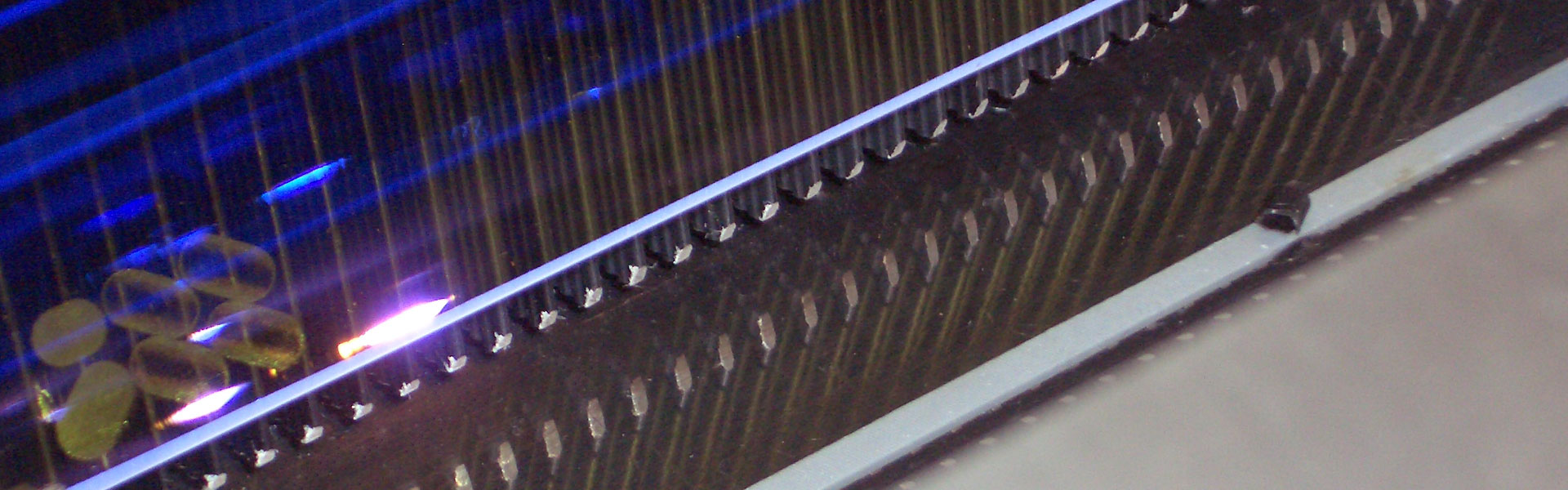

Significant results for all industrial UV-curing processes enabling an easy transfer from laboratory to production scale. Integrated sensors are monitoring the exposure intensity and ensure thereby an absolutely reproducible UV exposure on the substrates. The UV-systems of the ssr evo 7-series guarantee a photochemical polymerization free from harmful radiation heat. By use of the “Selective Lambda Technology", virtually no IR radiation is exposed to the substrates. This enables long exposure times without reaching the critical temperature of the substrates.

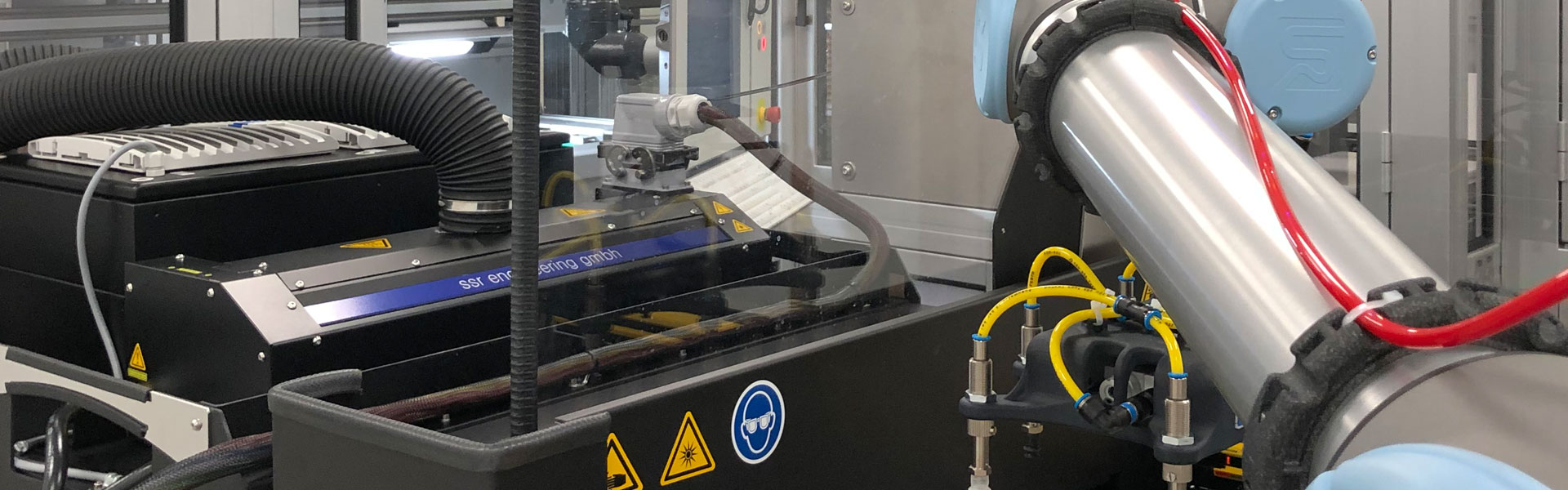

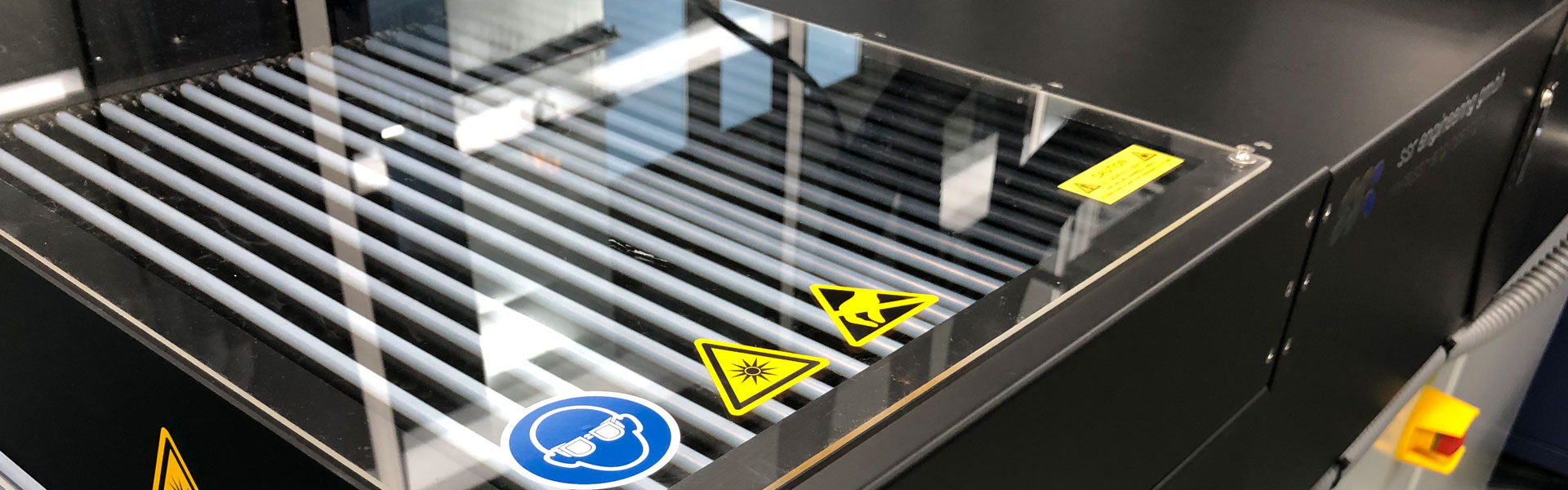

Designed as stand-alone unit, the system contains all necessary safety features. Its touch screen operator panel offers a maximum ease of use. The system contains an internal blower for sufficient air cooling. External water cooling is also required.

- Compact UV-curing station for laboratory and production / manufacturing

- Power setting 10 – 100 % step less

- The integrated mechanical shutter enables a precise time control of the exposure process

- Reproducible exposure programs

- Homogeneous exposure of the substrates

- Dosage controlled exposure

- Integrated cooling monitoring for a maximum of safety

- Interface for data transfer to a PC

- Inertization possible

- Customised system specifications on demand

Applications

- Curing and polymerisation of adhesives, lacquers, paints, inks and other coatings

- Precise evaluation of UV-curing processes for production

- Radiation for chemical and biological applications

- Low and ultra-high UV-dosages in defined spectral ranges:

UV-A 315 – 395 nm

UV-B 280 – 315 nm

UV-C 200 – 280 nm

UV-Vis 395 – 445 nm

Based on the cutting edge evo 7 – series UV curing systems, no relative movement between substrate and light source is required. The ultra high homogeneous exposure within the exposure area of the device, guarantees a reliable and reproducible curing process.

The UV-exposure station “ssr 2-207” presents a unique operational concept

in UV curing technology. Controlled by an internal PLC, all relevant process parameters such as curing power and curing time, are defined via the Siemens TP 277 Touch Panel. Its intuitionally surface is easy to use and offers a perfect outline of all operation modes.