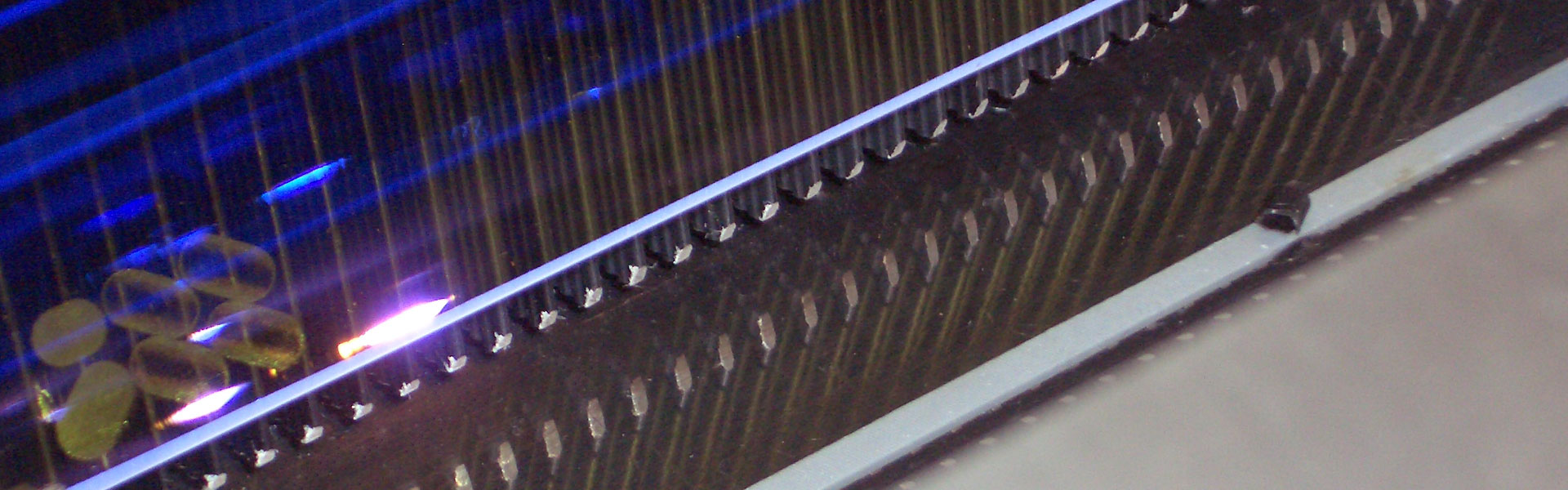

The UV system ssr evo 307 was specifically designed for the requirements of the plastic and electronic industry. The evo 307 is used for curing of clear and protective lacquers such as curing of screen printing inks. The Selective Lambda Technology offers a very pure process radiation in the UV and UV-Vis spectral area and thus providing a curing process with minimal thermal stress. As a result, the effective UV dose can be increased up to 500%.

An homogeneity of ± 3% in the exposure area allows static imaging processes with hitherto unknown precision. The evo 307 ideal for the production of high-quality and sensitive products like IMD foils, scratch resist coatings and SMD components.

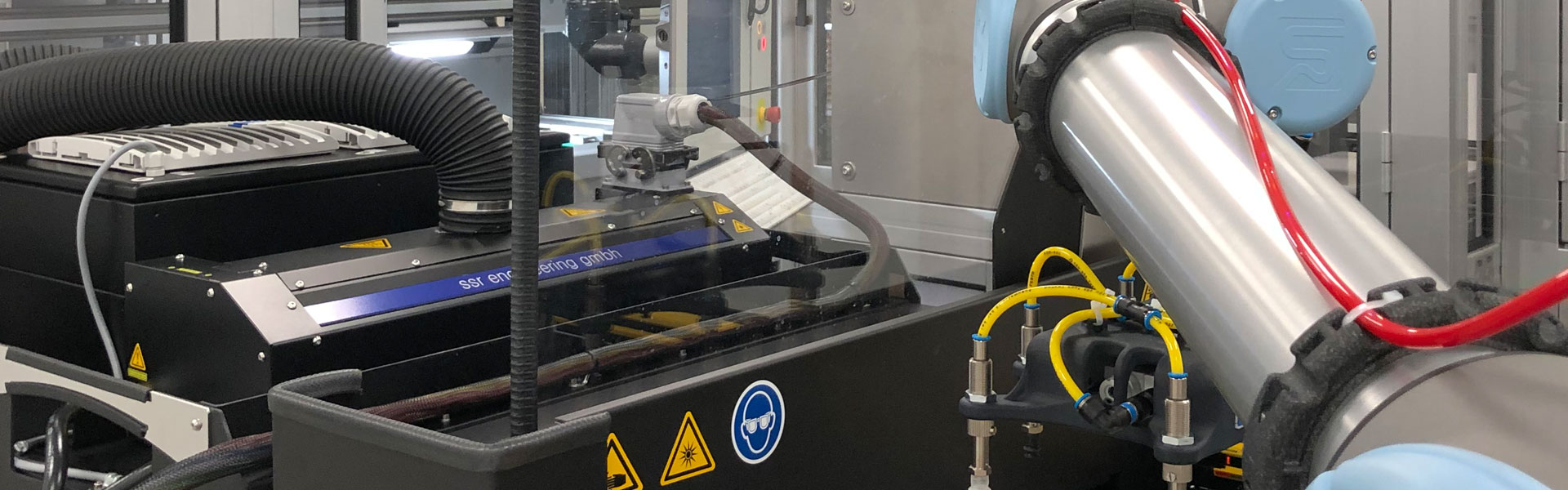

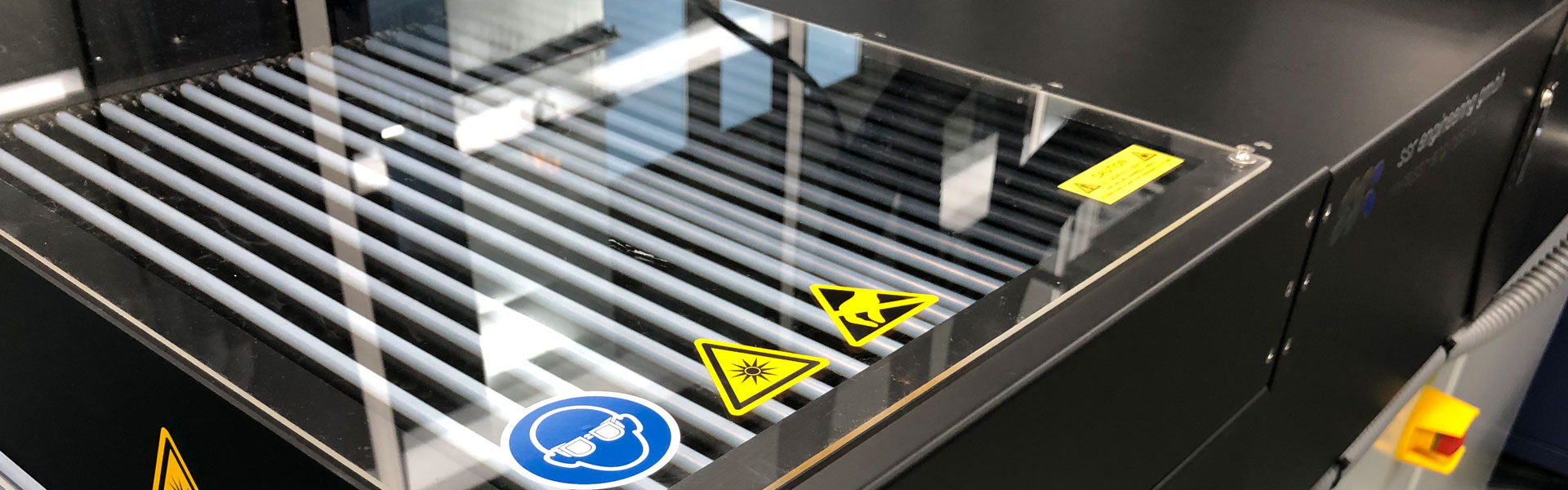

The evo 307 is also available as “evo 307 print” version. The consistent implementation of the compact design makes it the ideal UV system for integration in new and existing line equipment.

STRONG

EFFICIENT

FUTURE-PROOF